Erfolgsgeschichten

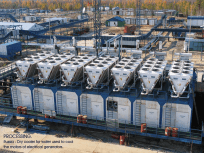

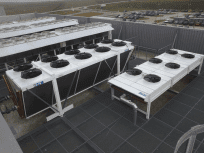

Lorca Planta Kondensation durch Rankine - Zyklus (Spanien)

Gründe für den Erfolg:

Energieeinsparung durch den Einsatz von EC – Motoren mit hoher Effizienz

Widerstandsfähige Lösung bei aggressiven Substanzen, dank der Alupaint - Lackierung

Bauqualität und Wirksamkeit

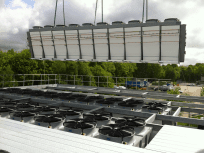

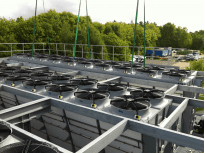

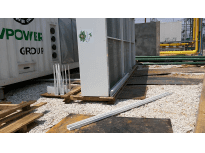

Almeria Wasserdampfkondensation durch thermodynamischen Kreisprozess (Spanien)

Gründe für den Erfolg:

Energieeinsparung durch den Einsatz von EC – Motoren mit hoher Effizienz

Bauqualität und Wirksamkeit

Lorca Planta Kondensation durch Rankine - Zyklus (Spanien)

Gründe für den Erfolg:

Energieeinsparung durch den Einsatz von EC – Motoren mit hoher Effizienz

Widerstandsfähige Lösung bei aggressiven Substanzen, dank der Alupaint - Lackierung

Bauqualität und Wirksamkeit

Almeria Wasserdampfkondensation durch thermodynamischen Kreisprozess (Spanien)

Gründe für den Erfolg:

Energieeinsparung durch den Einsatz von EC – Motoren mit hoher Effizienz

Bauqualität und Wirksamkeit