HOME > APLICACIONES > Refrigeración Industrial > INTERMARCHE’ LOGISTIC CENTER (TOLOSA AREA), installation of - CO2 industrial evaporators with hot glycol defrost. - industrial glycol air coolers - WSS dry coolers

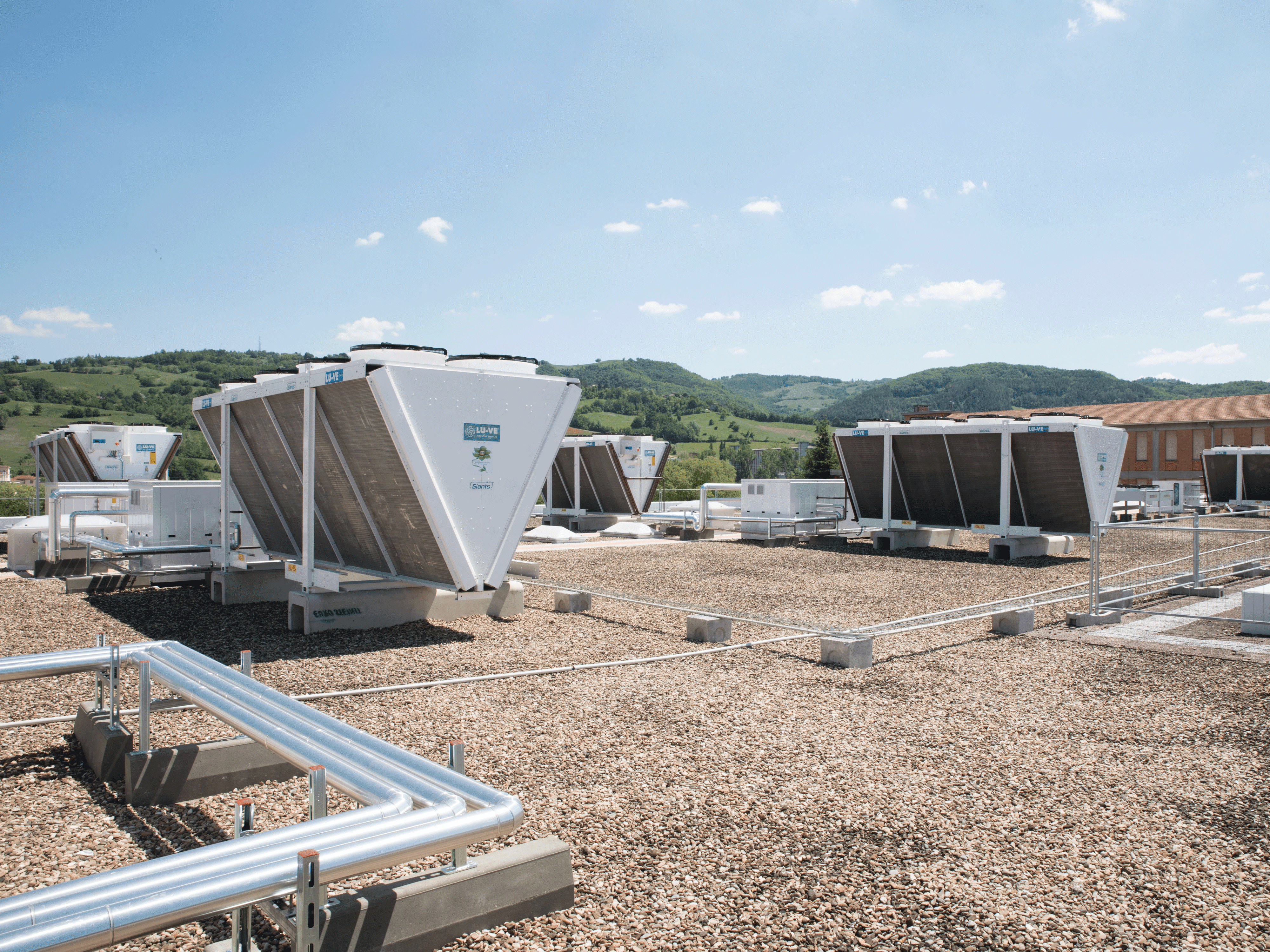

B&B Langhirano

Business: Industrial refrigeration

Application: Meat processing plant

Product: Air cooled condensers

Fluid: R407F

Country/City: Italy

Download PDF

Shandong Rongfeng Edible Mushroom co., ltd

(hereinafter as Rongfeng) is a hi-tech enterprise specializing in edible

mushroom industry with full strain of research and development.

Cultivation, Processing and Sales.

A staff of 600 people and 4 billion general assets. The factory, which

occupied more than 400 thousand square meters to supply large production

capability, can produce the impressive quantity 150 tons of mushrooms

each day. The main factory is in the Shangdong Region (northwest China)

at about 100 km from Jinan.

Rongfeng has the most advanced

process line in China, which had realized total automation from the

beginning to last procedure. The state of art process line provides the

best temperature, humidity, and ventilation with the installation of

light industrial LU-VE evaporator range F45H, F50HC and CD 45 double

flow range, for a total of 687 unit coolers with set of 114 screw

compressors (3,8 Mw) and also provides a guarantee for quality and

safety. The company has passed ISO/HACCP, and Organic products

certification.

Based on the most advanced process line, modern

management system, and the best human resource in China, this company

has become the biggest production base of Hypsizigus marmoreus.

(Including white beech mushroom, brown beech mushroom). Rongfeng was

awarded “National excellent leading company of Edible Fungus industry”

“Agricultural industrialization focus leading company” and so on.

Shandong Rongfeng Edible Mushroom co., ltd

(hereinafter as Rongfeng) is a hi-tech enterprise specializing in edible

mushroom industry with full strain of research and development.

Cultivation, Processing and Sales.

A staff of 600 people and 4 billion general assets. The factory, which

occupied more than 400 thousand square meters to supply large production

capability, can produce the impressive quantity 150 tons of mushrooms

each day. The main factory is in the Shangdong Region (northwest China)

at about 100 km from Jinan.

Rongfeng has the most advanced

process line in China, which had realized total automation from the

beginning to last procedure. The state of art process line provides the

best temperature, humidity, and ventilation with the installation of

light industrial LU-VE evaporator range F45H, F50HC and CD 45 double

flow range, for a total of 687 unit coolers with set of 114 screw

compressors (3,8 Mw) and also provides a guarantee for quality and

safety. The company has passed ISO/HACCP, and Organic products

certification.

Based on the most advanced process line, modern

management system, and the best human resource in China, this company

has become the biggest production base of Hypsizigus marmoreus.

(Including white beech mushroom, brown beech mushroom). Rongfeng was

awarded “National excellent leading company of Edible Fungus industry”

“Agricultural industrialization focus leading company” and so on.

Shandong Rongfeng Edible Mushroom co., ltd

(hereinafter as Rongfeng) is a hi-tech enterprise specializing in edible

mushroom industry with full strain of research and development.

Cultivation, Processing and Sales.

A staff of 600 people and 4 billion general assets. The factory, which

occupied more than 400 thousand square meters to supply large production

capability, can produce the impressive quantity 150 tons of mushrooms

each day. The main factory is in the Shangdong Region (northwest China)

at about 100 km from Jinan.

Rongfeng has the most advanced

process line in China, which had realized total automation from the

beginning to last procedure. The state of art process line provides the

best temperature, humidity, and ventilation with the installation of

light industrial LU-VE evaporator range F45H, F50HC and CD 45 double

flow range, for a total of 687 unit coolers with set of 114 screw

compressors (3,8 Mw) and also provides a guarantee for quality and

safety. The company has passed ISO/HACCP, and Organic products

certification.

Based on the most advanced process line, modern

management system, and the best human resource in China, this company

has become the biggest production base of Hypsizigus marmoreus.

(Including white beech mushroom, brown beech mushroom). Rongfeng was

awarded “National excellent leading company of Edible Fungus industry”

“Agricultural industrialization focus leading company” and so on.

Shandong Rongfeng Edible Mushroom co., ltd

(hereinafter as Rongfeng) is a hi-tech enterprise specializing in edible

mushroom industry with full strain of research and development.

Cultivation, Processing and Sales.

A staff of 600 people and 4 billion general assets. The factory, which

occupied more than 400 thousand square meters to supply large production

capability, can produce the impressive quantity 150 tons of mushrooms

each day. The main factory is in the Shangdong Region (northwest China)

at about 100 km from Jinan.

Rongfeng has the most advanced

process line in China, which had realized total automation from the

beginning to last procedure. The state of art process line provides the

best temperature, humidity, and ventilation with the installation of

light industrial LU-VE evaporator range F45H, F50HC and CD 45 double

flow range, for a total of 687 unit coolers with set of 114 screw

compressors (3,8 Mw) and also provides a guarantee for quality and

safety. The company has passed ISO/HACCP, and Organic products

certification.

Based on the most advanced process line, modern

management system, and the best human resource in China, this company

has become the biggest production base of Hypsizigus marmoreus.

(Including white beech mushroom, brown beech mushroom). Rongfeng was

awarded “National excellent leading company of Edible Fungus industry”

“Agricultural industrialization focus leading company” and so on.

Project name: G2 International LLC, Technopark Dubai

Refrigeration contractor: Fanar al Khaleej Refrigeration

Execution: 2017-2018

Application: Logistic cold store, dry cold store, chiller and freezer cold rooms

Application with hot gas defrost + electrical in parallel

Cooling system description:

- Chilled receiving area: LU-VE Cubic 2# F50HC 1806 E 7 - 40,6kW (10C_85%_EV-3) R404a

- 7 cold stores dual application Chiller/Freezer (various sizes): LU-VE Cubic 15# F50HC 1808 E 7 - 21,4kW (-20C_85%_EV-27C) R404a

- 2 cold stores dual application Chiller/Freezer (various sizes): LU-VE Cubic 4# F50HC 1806 E 7 - 17,4kW (-20C_85%_EV-27C) R404a

- 1 cold stores dual application Chiller/Freezer (various sizes): LU-VE Cubic 1# F45HC 1320 E 7 - 30,3kW (-20C_85%_EV-27C) R404a

- Corridor: LU-VE Cubic 2# F50HC 1706 E 6 - 40,6kW (5_85%_EV-3) R404a

- Dry storage area (1800sqm): LU-VE Cubic 3# F71HC 4208 N 6 – 65,8kW (22C_65%_EV-27C) R134a

- Technical Store: LU-VE Cubic 1# F45HC 1112 N 4 – 28,9kW (22C_65%_EV-27C) R134a

- Plant room: LU-VE Cubic 1# F35HC 261 N 6 – 19,4kW (25C_65%_EV-27C) R134a

Rack System:

- 1# Profroid 200HP Rack for LT application R404a

- 1# Profroid 120HP Rack for MT application R134a

Project name: G2 International LLC, Technopark Dubai

Refrigeration contractor: Fanar al Khaleej Refrigeration

Execution: 2017-2018

Application: Logistic cold store, dry cold store, chiller and freezer cold rooms

Application with hot gas defrost + electrical in parallel

Cooling system description:

- Chilled receiving area: LU-VE Cubic 2# F50HC 1806 E 7 - 40,6kW (10C_85%_EV-3) R404a

- 7 cold stores dual application Chiller/Freezer (various sizes): LU-VE Cubic 15# F50HC 1808 E 7 - 21,4kW (-20C_85%_EV-27C) R404a

- 2 cold stores dual application Chiller/Freezer (various sizes): LU-VE Cubic 4# F50HC 1806 E 7 - 17,4kW (-20C_85%_EV-27C) R404a

- 1 cold stores dual application Chiller/Freezer (various sizes): LU-VE Cubic 1# F45HC 1320 E 7 - 30,3kW (-20C_85%_EV-27C) R404a

- Corridor: LU-VE Cubic 2# F50HC 1706 E 6 - 40,6kW (5_85%_EV-3) R404a

- Dry storage area (1800sqm): LU-VE Cubic 3# F71HC 4208 N 6 – 65,8kW (22C_65%_EV-27C) R134a

- Technical Store: LU-VE Cubic 1# F45HC 1112 N 4 – 28,9kW (22C_65%_EV-27C) R134a

- Plant room: LU-VE Cubic 1# F35HC 261 N 6 – 19,4kW (25C_65%_EV-27C) R134a

Rack System:

- 1# Profroid 200HP Rack for LT application R404a

- 1# Profroid 120HP Rack for MT application R134a

Project name: G2 International LLC, Technopark Dubai

Refrigeration contractor: Fanar al Khaleej Refrigeration

Execution: 2017-2018

Application: Logistic cold store, dry cold store, chiller and freezer cold rooms

Application with hot gas defrost + electrical in parallel

Cooling system description:

- Chilled receiving area: LU-VE Cubic 2# F50HC 1806 E 7 - 40,6kW (10C_85%_EV-3) R404a

- 7 cold stores dual application Chiller/Freezer (various sizes): LU-VE Cubic 15# F50HC 1808 E 7 - 21,4kW (-20C_85%_EV-27C) R404a

- 2 cold stores dual application Chiller/Freezer (various sizes): LU-VE Cubic 4# F50HC 1806 E 7 - 17,4kW (-20C_85%_EV-27C) R404a

- 1 cold stores dual application Chiller/Freezer (various sizes): LU-VE Cubic 1# F45HC 1320 E 7 - 30,3kW (-20C_85%_EV-27C) R404a

- Corridor: LU-VE Cubic 2# F50HC 1706 E 6 - 40,6kW (5_85%_EV-3) R404a

- Dry storage area (1800sqm): LU-VE Cubic 3# F71HC 4208 N 6 – 65,8kW (22C_65%_EV-27C) R134a

- Technical Store: LU-VE Cubic 1# F45HC 1112 N 4 – 28,9kW (22C_65%_EV-27C) R134a

- Plant room: LU-VE Cubic 1# F35HC 261 N 6 – 19,4kW (25C_65%_EV-27C) R134a

Rack System:

- 1# Profroid 200HP Rack for LT application R404a

- 1# Profroid 120HP Rack for MT application R134a

Project name: G2 International LLC, Technopark Dubai

Refrigeration contractor: Fanar al Khaleej Refrigeration

Execution: 2017-2018

Application: Logistic cold store, dry cold store, chiller and freezer cold rooms

Application with hot gas defrost + electrical in parallel

Cooling system description:

- Chilled receiving area: LU-VE Cubic 2# F50HC 1806 E 7 - 40,6kW (10C_85%_EV-3) R404a

- 7 cold stores dual application Chiller/Freezer (various sizes): LU-VE Cubic 15# F50HC 1808 E 7 - 21,4kW (-20C_85%_EV-27C) R404a

- 2 cold stores dual application Chiller/Freezer (various sizes): LU-VE Cubic 4# F50HC 1806 E 7 - 17,4kW (-20C_85%_EV-27C) R404a

- 1 cold stores dual application Chiller/Freezer (various sizes): LU-VE Cubic 1# F45HC 1320 E 7 - 30,3kW (-20C_85%_EV-27C) R404a

- Corridor: LU-VE Cubic 2# F50HC 1706 E 6 - 40,6kW (5_85%_EV-3) R404a

- Dry storage area (1800sqm): LU-VE Cubic 3# F71HC 4208 N 6 – 65,8kW (22C_65%_EV-27C) R134a

- Technical Store: LU-VE Cubic 1# F45HC 1112 N 4 – 28,9kW (22C_65%_EV-27C) R134a

- Plant room: LU-VE Cubic 1# F35HC 261 N 6 – 19,4kW (25C_65%_EV-27C) R134a

Rack System:

- 1# Profroid 200HP Rack for LT application R404a

- 1# Profroid 120HP Rack for MT application R134a

Project name: G2 International LLC, Technopark Dubai

Refrigeration contractor: Fanar al Khaleej Refrigeration

Execution: 2017-2018

Application: Logistic cold store, dry cold store, chiller and freezer cold rooms

Application with hot gas defrost + electrical in parallel

Cooling system description:

- Chilled receiving area: LU-VE Cubic 2# F50HC 1806 E 7 - 40,6kW (10C_85%_EV-3) R404a

- 7 cold stores dual application Chiller/Freezer (various sizes): LU-VE Cubic 15# F50HC 1808 E 7 - 21,4kW (-20C_85%_EV-27C) R404a

- 2 cold stores dual application Chiller/Freezer (various sizes): LU-VE Cubic 4# F50HC 1806 E 7 - 17,4kW (-20C_85%_EV-27C) R404a

- 1 cold stores dual application Chiller/Freezer (various sizes): LU-VE Cubic 1# F45HC 1320 E 7 - 30,3kW (-20C_85%_EV-27C) R404a

- Corridor: LU-VE Cubic 2# F50HC 1706 E 6 - 40,6kW (5_85%_EV-3) R404a

- Dry storage area (1800sqm): LU-VE Cubic 3# F71HC 4208 N 6 – 65,8kW (22C_65%_EV-27C) R134a

- Technical Store: LU-VE Cubic 1# F45HC 1112 N 4 – 28,9kW (22C_65%_EV-27C) R134a

- Plant room: LU-VE Cubic 1# F35HC 261 N 6 – 19,4kW (25C_65%_EV-27C) R134a

Rack System:

- 1# Profroid 200HP Rack for LT application R404a

- 1# Profroid 120HP Rack for MT application R134a

Project name: Cold store and packaging facility for agri product in Cairo

Refrigeration contractor: MOG for Engineering and Industry, 10th of Ramadan Industrial City, Egypt

Execution 2018

Application: facility for collection, precooling, packaging and storage of various fruits and vegetables (lemon, oranges, strawberry, peas, pomegranate etc.). This project is part of a larger plan to develop the agricultural industry of Egypt, by boosting the facilities to serve the export market (Mainly northern Europe and Russia). Currently two additional cold store are under installation and commissioning.

Cooling system description:

- Chilled receiving area: LU-VE Dual Discharge 3# CD50H 9452 N 6 - 23,7kW (16C_85%_EV5) R407c

- 2 precooling rooms: LU-VE Cubic 4# CS71H 4416 E 10 - 67,3kW (0C_85%_EV-5C) R404a

- Production and packaging hall: LU-VE Dual Discharge 12# CD50H 9456 N 6 - 69,9kW (18C_85%_EV5) R407c

- 6 receiving rooms: LU-VE Cubic 6# CS62H 2218 N 6 - 140,8kW (15C_85%_EV5) R407c

- 6 cold stores: LU-VE Cubic 12# F50HC 1714 E 6 - 31,2kW (0C_85%_EV-5C) R404a

- Shipping area: LU-VE Dual Discharge 5# CD50H 9452 N 6 - 23,7kW (16C_85%_EV5) R404a

Rack System:

- 4# Emerson 200HP Rack for MT application R407c – 4# LU-VE Condensers EHV90F 374 H 8VENT (2X4)

- 2# Emerson 180HP Rack for LT application R404a – 2# LU-VE Condensers EAV8S 7231 H 6VENT (2X3)

- 1# Emerson 200HP Rack for LT application R404a – 1# LU-VE Condensers EHV90F 368 H 6VENT (2X3)

Project name: Cold store and packaging facility for agri product in Cairo

Refrigeration contractor: MOG for Engineering and Industry, 10th of Ramadan Industrial City, Egypt

Execution 2018

Application: facility for collection, precooling, packaging and storage of various fruits and vegetables (lemon, oranges, strawberry, peas, pomegranate etc.). This project is part of a larger plan to develop the agricultural industry of Egypt, by boosting the facilities to serve the export market (Mainly northern Europe and Russia). Currently two additional cold store are under installation and commissioning.

Cooling system description:

- Chilled receiving area: LU-VE Dual Discharge 3# CD50H 9452 N 6 - 23,7kW (16C_85%_EV5) R407c

- 2 precooling rooms: LU-VE Cubic 4# CS71H 4416 E 10 - 67,3kW (0C_85%_EV-5C) R404a

- Production and packaging hall: LU-VE Dual Discharge 12# CD50H 9456 N 6 - 69,9kW (18C_85%_EV5) R407c

- 6 receiving rooms: LU-VE Cubic 6# CS62H 2218 N 6 - 140,8kW (15C_85%_EV5) R407c

- 6 cold stores: LU-VE Cubic 12# F50HC 1714 E 6 - 31,2kW (0C_85%_EV-5C) R404a

- Shipping area: LU-VE Dual Discharge 5# CD50H 9452 N 6 - 23,7kW (16C_85%_EV5) R404a

Rack System:

- 4# Emerson 200HP Rack for MT application R407c – 4# LU-VE Condensers EHV90F 374 H 8VENT (2X4)

- 2# Emerson 180HP Rack for LT application R404a – 2# LU-VE Condensers EAV8S 7231 H 6VENT (2X3)

- 1# Emerson 200HP Rack for LT application R404a – 1# LU-VE Condensers EHV90F 368 H 6VENT (2X3)

Project name: Cold store and packaging facility for agri product in Cairo

Refrigeration contractor: MOG for Engineering and Industry, 10th of Ramadan Industrial City, Egypt

Execution 2018

Application: facility for collection, precooling, packaging and storage of various fruits and vegetables (lemon, oranges, strawberry, peas, pomegranate etc.). This project is part of a larger plan to develop the agricultural industry of Egypt, by boosting the facilities to serve the export market (Mainly northern Europe and Russia). Currently two additional cold store are under installation and commissioning.

Cooling system description:

- Chilled receiving area: LU-VE Dual Discharge 3# CD50H 9452 N 6 - 23,7kW (16C_85%_EV5) R407c

- 2 precooling rooms: LU-VE Cubic 4# CS71H 4416 E 10 - 67,3kW (0C_85%_EV-5C) R404a

- Production and packaging hall: LU-VE Dual Discharge 12# CD50H 9456 N 6 - 69,9kW (18C_85%_EV5) R407c

- 6 receiving rooms: LU-VE Cubic 6# CS62H 2218 N 6 - 140,8kW (15C_85%_EV5) R407c

- 6 cold stores: LU-VE Cubic 12# F50HC 1714 E 6 - 31,2kW (0C_85%_EV-5C) R404a

- Shipping area: LU-VE Dual Discharge 5# CD50H 9452 N 6 - 23,7kW (16C_85%_EV5) R404a

Rack System:

- 4# Emerson 200HP Rack for MT application R407c – 4# LU-VE Condensers EHV90F 374 H 8VENT (2X4)

- 2# Emerson 180HP Rack for LT application R404a – 2# LU-VE Condensers EAV8S 7231 H 6VENT (2X3)

- 1# Emerson 200HP Rack for LT application R404a – 1# LU-VE Condensers EHV90F 368 H 6VENT (2X3)

Project name: Cold store and packaging facility for agri product in Cairo

Refrigeration contractor: MOG for Engineering and Industry, 10th of Ramadan Industrial City, Egypt

Execution 2018

Application: facility for collection, precooling, packaging and storage of various fruits and vegetables (lemon, oranges, strawberry, peas, pomegranate etc.). This project is part of a larger plan to develop the agricultural industry of Egypt, by boosting the facilities to serve the export market (Mainly northern Europe and Russia). Currently two additional cold store are under installation and commissioning.

Cooling system description:

- Chilled receiving area: LU-VE Dual Discharge 3# CD50H 9452 N 6 - 23,7kW (16C_85%_EV5) R407c

- 2 precooling rooms: LU-VE Cubic 4# CS71H 4416 E 10 - 67,3kW (0C_85%_EV-5C) R404a

- Production and packaging hall: LU-VE Dual Discharge 12# CD50H 9456 N 6 - 69,9kW (18C_85%_EV5) R407c

- 6 receiving rooms: LU-VE Cubic 6# CS62H 2218 N 6 - 140,8kW (15C_85%_EV5) R407c

- 6 cold stores: LU-VE Cubic 12# F50HC 1714 E 6 - 31,2kW (0C_85%_EV-5C) R404a

- Shipping area: LU-VE Dual Discharge 5# CD50H 9452 N 6 - 23,7kW (16C_85%_EV5) R404a

Rack System:

- 4# Emerson 200HP Rack for MT application R407c – 4# LU-VE Condensers EHV90F 374 H 8VENT (2X4)

- 2# Emerson 180HP Rack for LT application R404a – 2# LU-VE Condensers EAV8S 7231 H 6VENT (2X3)

- 1# Emerson 200HP Rack for LT application R404a – 1# LU-VE Condensers EHV90F 368 H 6VENT (2X3)

Project name: Cold store and packaging facility for agri product in Cairo

Refrigeration contractor: MOG for Engineering and Industry, 10th of Ramadan Industrial City, Egypt

Execution 2018

Application: facility for collection, precooling, packaging and storage of various fruits and vegetables (lemon, oranges, strawberry, peas, pomegranate etc.). This project is part of a larger plan to develop the agricultural industry of Egypt, by boosting the facilities to serve the export market (Mainly northern Europe and Russia). Currently two additional cold store are under installation and commissioning.

Cooling system description:

- Chilled receiving area: LU-VE Dual Discharge 3# CD50H 9452 N 6 - 23,7kW (16C_85%_EV5) R407c

- 2 precooling rooms: LU-VE Cubic 4# CS71H 4416 E 10 - 67,3kW (0C_85%_EV-5C) R404a

- Production and packaging hall: LU-VE Dual Discharge 12# CD50H 9456 N 6 - 69,9kW (18C_85%_EV5) R407c

- 6 receiving rooms: LU-VE Cubic 6# CS62H 2218 N 6 - 140,8kW (15C_85%_EV5) R407c

- 6 cold stores: LU-VE Cubic 12# F50HC 1714 E 6 - 31,2kW (0C_85%_EV-5C) R404a

- Shipping area: LU-VE Dual Discharge 5# CD50H 9452 N 6 - 23,7kW (16C_85%_EV5) R404a

Rack System:

- 4# Emerson 200HP Rack for MT application R407c – 4# LU-VE Condensers EHV90F 374 H 8VENT (2X4)

- 2# Emerson 180HP Rack for LT application R404a – 2# LU-VE Condensers EAV8S 7231 H 6VENT (2X3)

- 1# Emerson 200HP Rack for LT application R404a – 1# LU-VE Condensers EHV90F 368 H 6VENT (2X3)

Potato Cold Storage for Lays (PepsiCo) in Turkey.

Condensers:

4 x XDHV1X 4145+SUBC+EC+GRILLE

Evaporators:

8 x LS50H 5824 E 7

+ INOX BODY

+EC FANS

Prestigious customer with similar cold store.

It has been proved that the reduction of energy consumption (coupled with Polaref raks, with Bitzer compressor) is 45 to 50% yearly.

Challenge of maintaining the humidity at 97%, and 1°C decrease in temperature every 12 hours.

Carrefour Masdar City

Super market cold stores and preparation rooms

Evaporator:

20 x F31HC/F35HC CO2, FHD CO2,

Gas Cooler:

1 x SAV9T 3232 CO2 + P25 + EC + IS

First CO2 installation in the GCC countries.

Masdar City is the first sustainable city in the GCC, where “green” initiatives are implemented.

Technical challenge: CO2 transcritical in an area that reaches 50°C, made possible by LU-VE adiabatic dry cooler.

Carrefour Masdar City

Super market cold stores and preparation rooms

Evaporator:

20 x F31HC/F35HC CO2, FHD CO2,

Gas Cooler:

1 x SAV9T 3232 CO2 + P25 + EC + IS

First CO2 installation in the GCC countries.

Masdar City is the first sustainable city in the GCC, where “green” initiatives are implemented.

Technical challenge: CO2 transcritical in an area that reaches 50°C, made possible by LU-VE adiabatic dry cooler.

Carrefour Masdar City

Super market cold stores and preparation rooms

Evaporator:

20 x F31HC/F35HC CO2, FHD CO2,

Gas Cooler:

1 x SAV9T 3232 CO2 + P25 + EC + IS

First CO2 installation in the GCC countries.

Masdar City is the first sustainable city in the GCC, where “green” initiatives are implemented.

Technical challenge: CO2 transcritical in an area that reaches 50°C, made possible by LU-VE adiabatic dry cooler.

LU-VE S.p.A. - Via Caduti della Liberazione, 53 21040 UBOLDO (Va) - Tel: +39 02 96716.1, e-mail: sales@luvegroup.com

REA Varese N°191975 - Capitale sociale € 62.704.488,80 (i.v.) - P. IVA 01570130128

In order to improve users browsing experience this website uses cookies. By keeping on browsing this website, you agree to the placement of cookies on your computer. For further informations and cookies deactivation, please refer to the advisory notice.