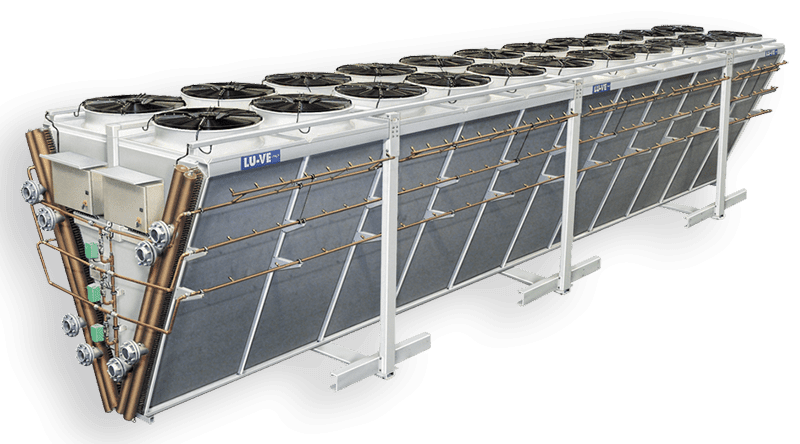

Adiabatic condensers and dry coolers with special Spray System D&S

General principles

Dry coolers and condensers are normally selected to operate correctly at maximum thermal load with maximum ambient temperature.

However, these severe working conditions apply only to a brief period of the year whilst for the remainder of the year - in less severe conditions – the machine is oversized. This is why LU-VE designed a unit which can be selected for standard working conditions but which can increase its performance when particularly severe conditions arise.

The innovative DRY AND SPRAY® system, thanks to its special nozzle configuration, can use softened water for up to 900 working hours per year.