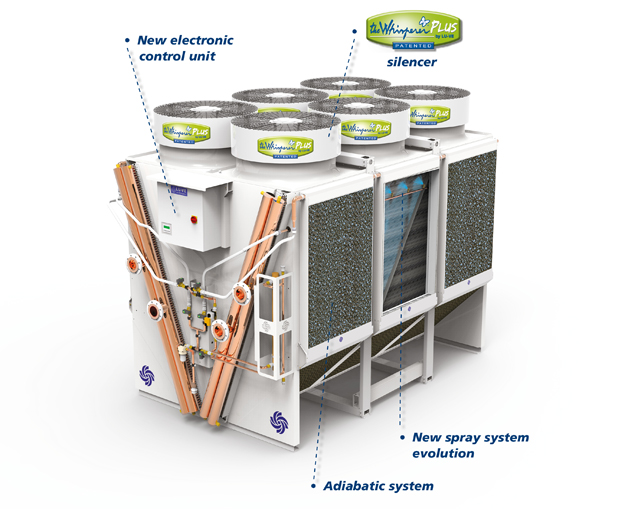

EMERITUS®

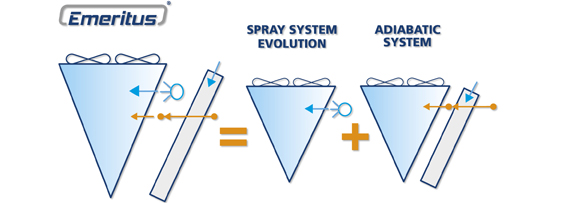

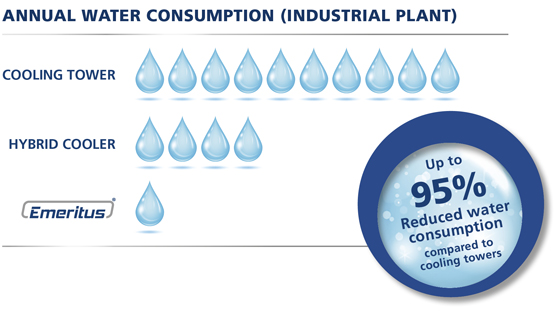

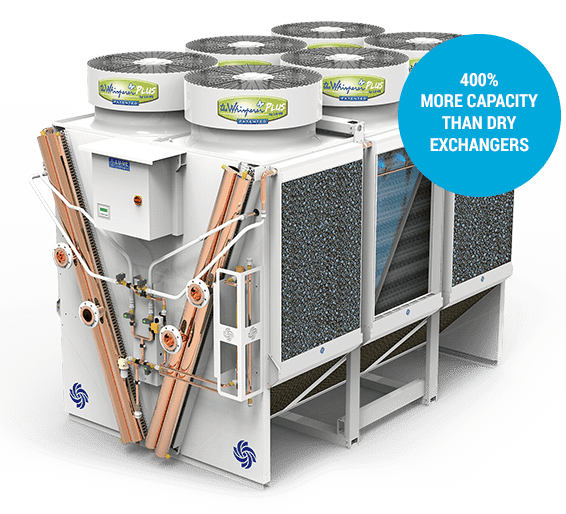

The new combined spray + adiabatic system

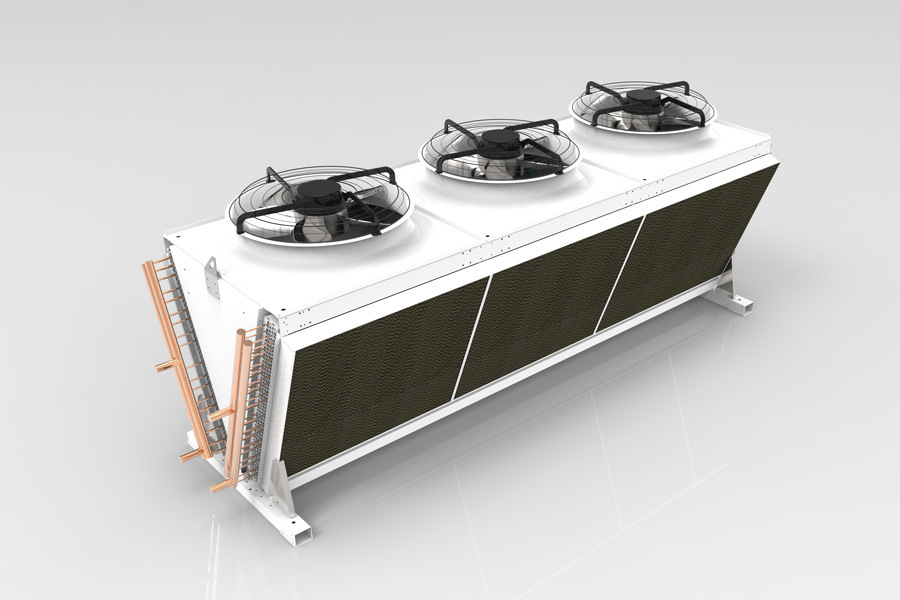

400% MORE CAPACITY THAN A DRY EXCHANGER

EMERITUS® is the latest innovation developed for the dry cooler, condenser and CO2 gas cooler families from LU-VE Exchangers.

Available for: HFC, NH3, Propane, CO2