CO2: the natural leader

Today LU-VE can state that it has the highest technical level and greatest experience in this particular field.

Numerous unit coolers and gas coolers have been installed in different countries in recent years.

CO2, the preferred solution. WHAT CAN LU-VE OFFER?

| High performance heat exchangers |

| Reliable performance and know how (laboratory testing plant) |

| Experience in trans-critical installations running for more than 10 YEARS |

| Complete range of industrial and commercial evaporators (40 bar, 60 bar, 85 bar) and Gas Coolers (120 bar) |

The utilization of CO2 fluid in the refrigeration industry

In the refrigeration industry, the utilization of CO2 fluid is becoming more and more popular as a radical solution to eliminate the greenhouse effect caused by halogenated hydrocarbons in the HFC category.

The GWP (Global Warming Potential) of CO2 is in fact very low compared to HFCs (1 against several thousands); also, CO2 does not present any problems of toxicity, flammability nor of impact on the ozone layer. CO2 is significantly different from all the traditional HFCs (R404A, R507, ...) and it poses particular problems for heat exchanger designers; in addition, the appropriate choice of heat exchanger technology is fundamentally important in the realization of high efficiency CO2 plants.

The real challenge is to design plant with an efficiency level equal to or higher than current HFC plants.

LU-VE decided to invest in CO2, designing a test plant in the laboratory.

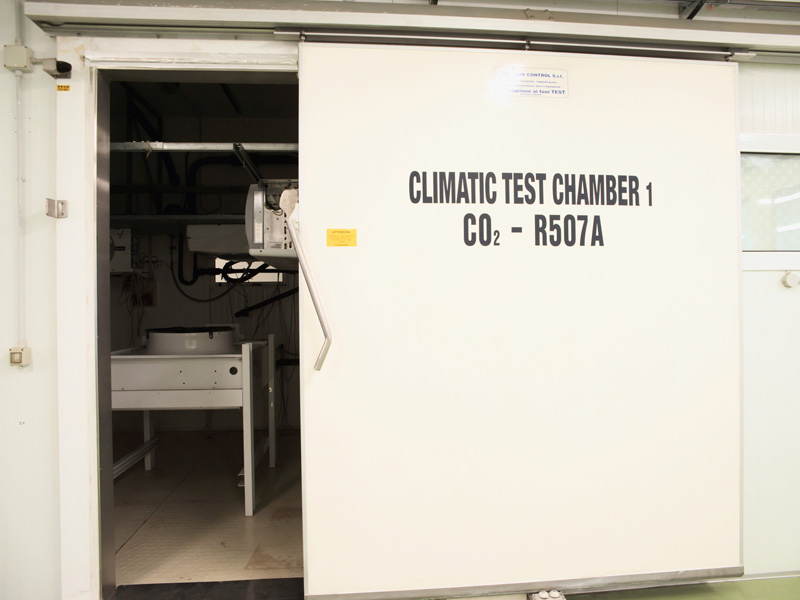

The test equipment is made up of a climatic room operating at a constant temperature.

It is the only plant with such characteristics available in Europe dedicated to heat exchangers.

There is a serious risk that the use of CO2 may not be entirely good, regarding greenhouse effect mitigation. Even though the direct contribution is practically zero, the indirect effect would be increased if the CO2 refrigeration cycles were less efficient than traditional ones, due to larger electricity consumption bringing about larger emissions of CO2 and of other pollutants from power stations, consuming more fossil fuels. For this reason, it is always worth bearing in mind that the technical solutions used to improve the environmental aspects cannot disregard the achievement of elevated thermodynamic efficiency.

LU-VE has designed very efficient heat exchangers for CO2 applications and has been able to make important developments thanks to the use of its modern test ring.

This plant can test the performance of CO2 finned heat exchangers, both air cooled unit coolers and gas coolers.

The new testing plant enabled the launch of a specific project for a CO2 fin-and-tube heat exchanger, with the primary aim of improving knowledge of heat exchange phenomena in evaporation, condensation and during trans-critical gas cooling.

The appropriate choice of heat exchanger technology is a fundamental condition for obtaining COP values from CO2 cycles allowing for a real reduction of the greenhouse effect.

For these reasons, a specific project between LU-VE, Politecnico di Milano and some important customers was carried out in order to define the ideal product configuration to get the best out of the specific characteristics of this refrigerant and to obtain interesting benefits from it.

The influence of oil on internal heat exchange coefficient also enters into the scope of the research.

Important is the calibration made on software that calculates very precisely product performance, with potential improvements to products.

In particular, it was possible to calibrate a specific method able to take into account the behaviour of the fluid during trans-critical cooling, properly considering all the parameters affecting real performance.